Industrial

Machines

Industrial

With a steadfast commitment to excellence, innovation, and customer satisfaction.

Innox is ready to deliver cutting-edge machinery and equipment that enhances productivity, efficiency, cost-effectiveness & competitiveness of our valued clients.

(SEAM, SPOT, PROJECTION)

(SURFACE, CG AND CETERLESS)

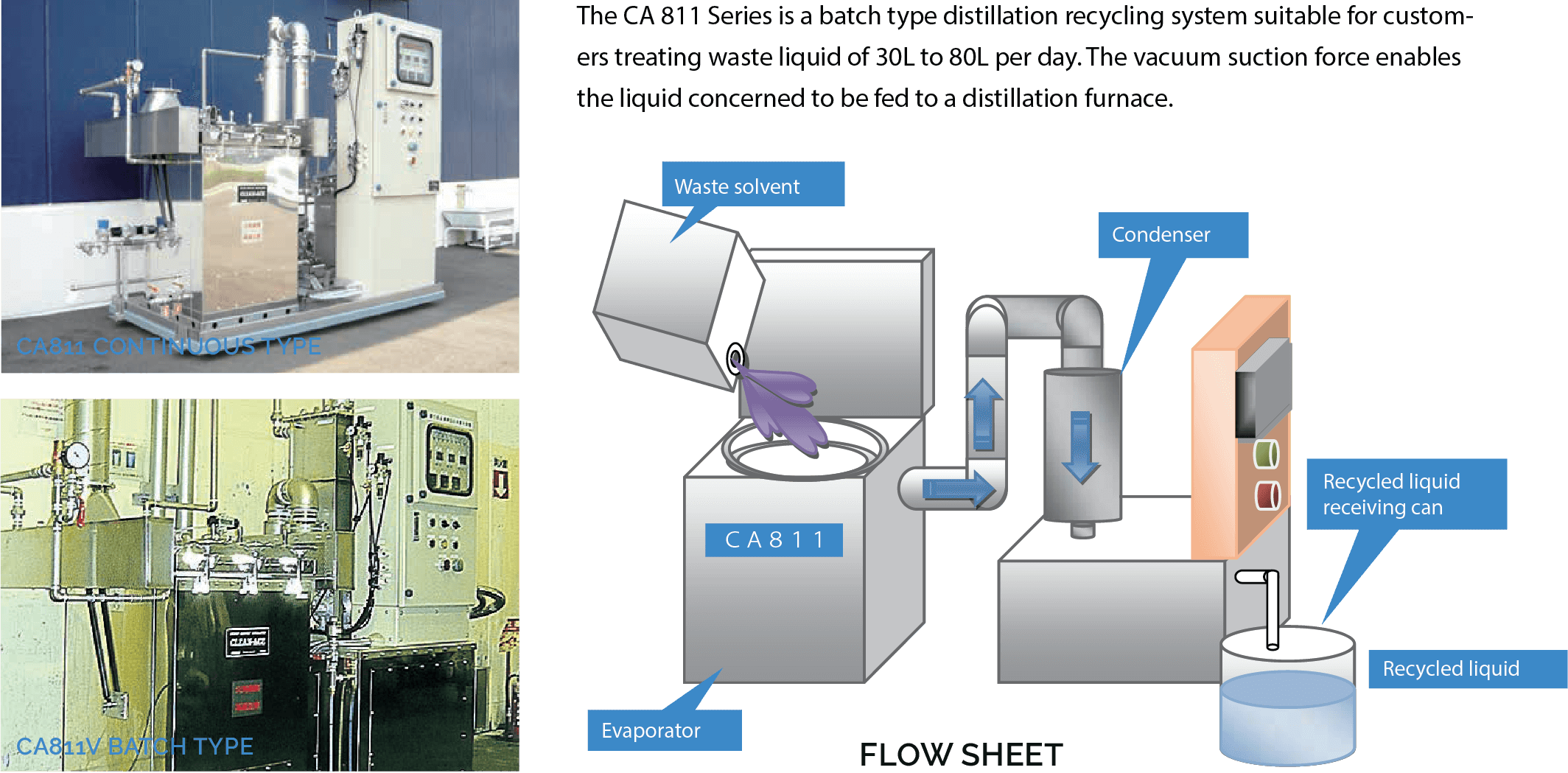

SOLVENT RECYCLING SYSTEM FROM JAPAN

SYSTEM SPECIFICATIONS

| Model | CA811 batch type | CA811V batch type | CA811 continuous type | CA811V continuous type |

|---|---|---|---|---|

| Treatment method | Normal pressure | Vacuum | Normal pressure | Vacuum |

|

Treatment capacity (100% toluenecontent) |

40L at a time | 40L at a time | 15L/Hr | 15L/hr |

| Heating System | Heat pipe system or steam type | |||

| Power supply | AC200V | |||

| Chiller unit | Option | |||

| Required utility | Electricity, air, cooling water and steam | |||

Applicable solvents;

Petroleum containing adhesives, paint, resin, ink, metal powder,

machining oil, etc. (toluene, MEK, acetone, ethyl acetate, alcohols

[IPA, methanol and ethanol]).

Petroleum (xylene, etc.), hydrocarbon-based cleaning solvents,

fluorocarbon-based liquid, etc.